In addition to brush and roller application, most industrial coatings can also be applied using common spray applications. The Korthals Group distinguishes between spray coatings for wood and metal. An overview.

| Coating Type | Metal | Wood |

| Appearance Form | Wet paint, powder coating. | Wet paint. |

| Layer buildup | Metal primer (a primer can often be omitted on stainless steel); topcoat: one layer 40 μm (dry). | Wood primer; topcoat: one layer sufficient. |

| Preparation | Make substrate grease- and dust-free. Some coating systems require application on blasted substrate (SA 2.5). | Make substrate grease- and dust-free. Sand with P15 grit. |

| Drying time | Varies greatly depending on coating and drying method. | 30-45 min., depending on ambient temperature. |

| Colorability | Virtually all color possibilities (inquire about options). For our specialty coatings, there are limitations; discover color options through our advisory tools. | Topcoat available in E- and CBM colors (other colors on request). Color result depends on the wood species to be coated. |

| Spray Application | Pneumatic, airless, airmix. | Pneumatic, airless, airmix. |

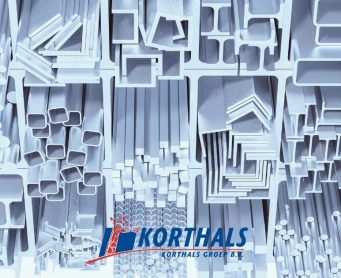

| Suitable Substrates | Steel, stainless steel, aluminum, brass, copper, various other alloys (inquire about options). | Essentially all wood species. |

| Application Area/Industry | Machinery, offshore/petrochemical, roller and overhead doors, and much more… | Furniture industry, shipbuilding/yacht construction, interior construction, and much more… |

The main advantages of spray coatings:

At the Korthals Group, we like to think in terms of possibilities. Our coatings offer (a mix of) the following properties:

Still not sure what the right industrial coating is for your situation and usage preferences? Our experts are here to help. After years of experience and extensive testing in our own laboratory, spray coatings hold no secrets for us anymore! Contact us now for personalized advice without obligation.

Get in touchSpray coating is known for its fast application speed and efficiency. By using specialized spraying equipment, large surfaces can be covered evenly and quickly, significantly reducing the time compared to traditional roller or brush methods. This leads to faster project completion times and minimizes equipment or facility downtime. (Important to note: material consumption is higher when spraying compared to brushing and rolling.)

Spray coatings offer various possibilities for customization in terms of color and finish. We can mix colors to precisely meet your specifications. Moreover, there are various finishing options available, from matte to high gloss. With our formulations, properties such as UV protection, anti-slip, and enhanced chemical resistance can be achieved. Customized coating solutions are also possible.

Safety measures are required during the application of spray coatings to protect the health of applicators and the environment. This includes the use of personal protective equipment (PPE), such as masks, gloves, and safety goggles. Ensure adequate ventilation to minimize inhalation of fumes and aerosols. Check local regulations and consult the Safety Data Sheet provided by us for more information and proper precautions before use.

Spray coating is versatile enough to be used in both indoor and outdoor applications. The choice of coating type depends on the specific requirements of the application, such as UV stability for outdoor use. Proper preparation and selection of the coating ensure that the end result provides both durable protection and aesthetic appeal, regardless of the location.